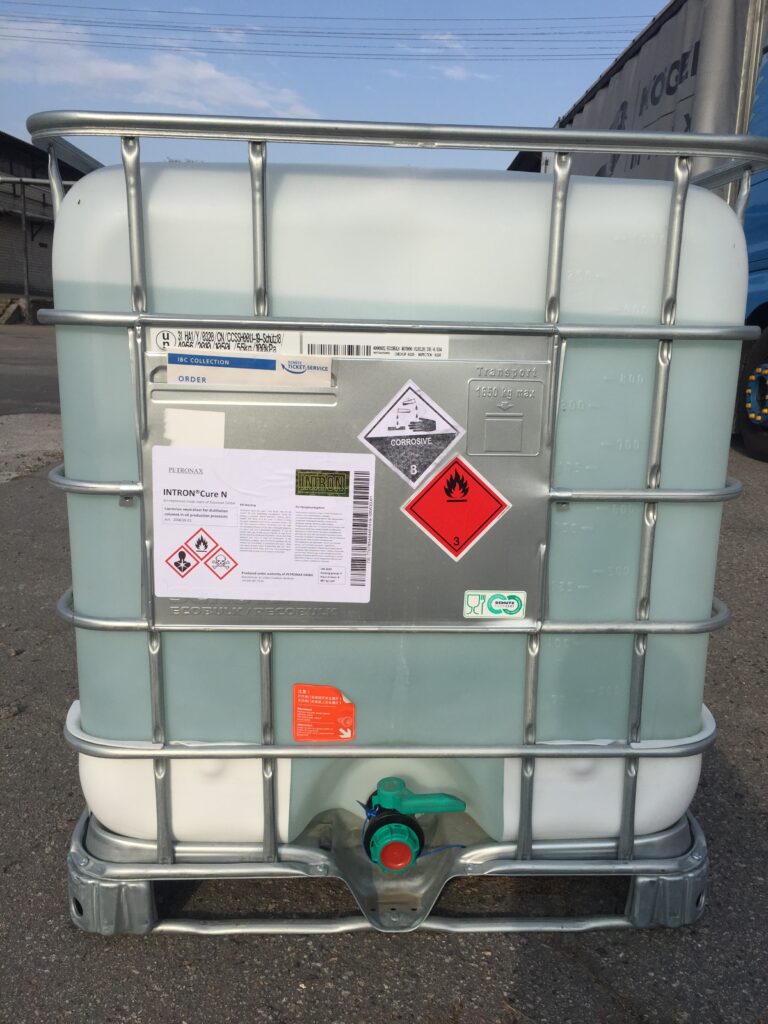

Corrosion is a significant concern in refinery distillation columns, impacting their efficiency and longevity. These columns are exposed to harsh conditions, such as high temperatures, pressure, and corrosive chemicals, which can lead to metal degradation. Fortunately, Petronax offers an effective solution called INTRON antiCorr.

INTRON antiCorr, developed by Petronax, is a specialized corrosion inhibitor designed specifically for refinery distillation columns. It is formulated to provide superior protection against corrosion and extend the lifespan of these critical assets.

The unique formulation of INTRON antiCorr creates a protective layer on the metal surfaces, shielding them from corrosive elements. This layer acts as a barrier, preventing the interaction between the metal and corrosive substances present in the column. By inhibiting corrosion, INTRON antiCorr helps to maintain the structural integrity of the distillation column and ensures optimal performance.

The application of INTRON antiCorr is simple and can be integrated into existing maintenance processes. It can be injected into the column at specific locations or circulated throughout the system. The inhibitor’s long-lasting effectiveness reduces the frequency of application, resulting in cost savings and increased operational efficiency.

Furthermore, INTRON antiCorr is compatible with various types of refinery distillation columns and can be used in different operating conditions. This versatility makes it suitable for a wide range of applications in the refining industry.

Petronax’s INTRON antiCorr is a reliable solution that addresses corrosion problems in refinery distillation columns. By protecting against corrosion and extending the lifespan of these critical assets, it helps refineries maintain smooth operations, improve safety, and reduce maintenance costs