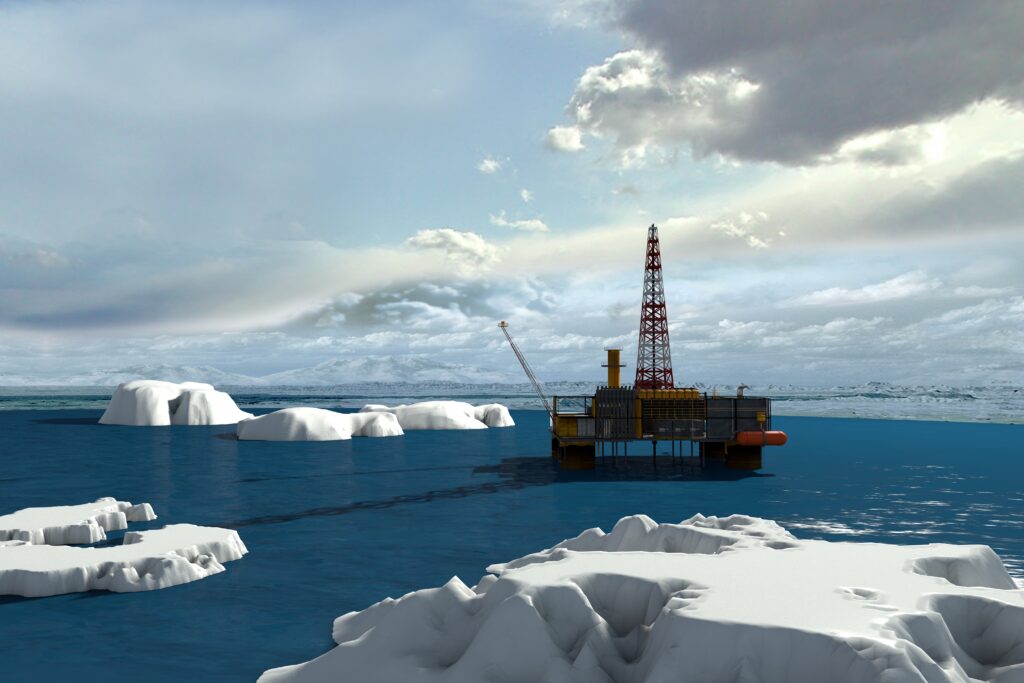

Exploration and drilling of crude oil is a complex process that involves a range of chemical techniques and technologies. The process begins with geological surveys and geophysical exploration, which involve the analysis of rock formations and seismic activity to identify potential oil reserves. Once a potential reserve has been identified, exploratory drilling is conducted to determine the quantity and quality of the oil.

Chemical Techniques Used in Exploration and Drilling

There are several chemical techniques used in the exploration and drilling of crude oil, including:

Geochemical analysis: This technique involves the analysis of rock and soil samples to identify the presence of hydrocarbons, which are the main components of crude oil. Geochemical analysis can also help to determine the quality of the oil, including its API gravity, sulfur content, and other properties.

Seismic surveys: Seismic surveys involve the use of sound waves to create images of the subsurface of the earth. These images can help to identify potential oil reserves and determine the best location for drilling.

Hydraulic fracturing: Hydraulic fracturing, also known as fracking, involves the injection of chemicals and water into the rock formations to fracture them and release the trapped oil and gas. This technique has been controversial due to its potential environmental impacts.

Enhanced oil recovery: Enhanced oil recovery techniques involve the injection of chemicals, water, or steam into the reservoir to increase the flow of oil to the surface. These techniques can help to recover more oil from the reservoir and extend the life of the well.

Chemical Technologies Used in Drilling

In addition to chemical techniques, there are several chemical technologies used in the drilling process, including:

Drilling muds: Drilling muds are a type of fluid that is used to lubricate the drill bit, cool the drill string, and carry the rock cuttings to the surface. Drilling muds can be formulated with a range of chemicals, including polymers, clays, and additives, to improve their performance.

Cementing: Cementing is the process of creating a seal between the wellbore and the surrounding rock formations. Cement is pumped into the wellbore and allowed to set, creating a barrier that prevents the oil and gas from escaping into the surrounding rock formations.

Corrosion inhibitors: Corrosion inhibitors are chemicals that are added to the drilling fluid or wellbore to prevent corrosion of the drill string and production tubing. Corrosion can lead to equipment failure and contamination of the oil.

Scale inhibitors: Scale inhibitors are chemicals that are added to the drilling fluid or wellbore to prevent the buildup of mineral deposits, or scale, on the production tubing. Scale can reduce the flow of oil and gas and increase the cost of production.

Exploration and drilling of crude oil are complex processes that involve a range of chemical techniques and technologies. These techniques and technologies are essential for identifying potential oil reserves, determining the quality of the oil, and extracting the oil from the reservoir. The use of chemicals in exploration and drilling can improve the efficiency and effectiveness of the process, but it is important to use them responsibly and to minimize their impact on the environment. Companies like PETRONAX are leading the way in the development and production of chemical products that are safe and effective for use in the exploration and drilling of crude oil. Their experience and expertise in this field make them a trusted partner for oil and gas companies worldwide

Our core solutions for exploration and drilling processes

- INTRON antiCorr – corrosion inhibitors

- INTRON antiScale – scale inhibitors

- INTRON dSol – demulsifier series

- INTRON dFlow – crude oil Flow Improvers (COFI)

- INTRON cWax – wax Inhibitors (WASA)