Deposit control additives

Deposit control additives are chemicals that are added to fuels to prevent the formation of deposits on engine components. These deposits can cause significant damage to engines, leading to decreased performance, increased fuel consumption, and higher maintenance costs.

The formation of deposits is a common problem in internal combustion engines. As fuel burns, it leaves behind various residues that can accumulate on engine components such as fuel injectors, intake valves, and combustion chambers. Over time, these deposits can become so thick that they restrict fuel flow, reduce engine performance, and cause mechanical failure.

To prevent these issues, deposit control additives are formulated to clean and maintain engine components. These additives are designed to dissolve and remove deposits that may have already formed, as well as prevent new deposits from accumulating.

Deposit control additives work in a variety of ways. Some act as detergents, breaking down deposits into smaller particles that can be easily removed. Others work as dispersants, keeping the deposits in suspension so they can be safely carried away by the fuel. Still, others work by modifying the chemistry of the fuel to prevent deposits from forming in the first place.

The most common types of deposit control additives are detergents. These additives work by breaking down carbonaceous deposits, which are composed of hydrocarbons that have been partially oxidized during combustion. Detergent additives contain polar molecules that are attracted to the surface of the deposits, causing them to dislodge and dissolve.

In addition to detergents, other types of deposit control additives include dispersants and metal deactivators. Dispersants work by keeping deposits suspended in the fuel, preventing them from settling onto engine components. Metal deactivators work by sequestering metal ions in the fuel, which can otherwise act as catalysts for deposit formation.

Deposit control additives are particularly important for vehicles that operate under challenging conditions. Vehicles that are driven in stop-and-go traffic or that are used for frequent short trips may be more prone to deposit formation than those that are used for longer, steady-state trips.

In addition, some types of fuel are more prone to deposit formation than others. Diesel fuels, for example, are known to be more prone to deposit formation than gasoline fuels. This is due to the high carbon content of diesel fuel, which can lead to the formation of thick carbonaceous deposits.

To combat these challenges, many fuel companies offer deposit control additives as an option for their customers. These additives can be added to the fuel at the pump, providing a convenient and effective way to protect engines from deposit formation.

In addition to improving engine performance, deposit control additives can also have environmental benefits. By keeping engines clean, these additives can help to reduce emissions and improve fuel efficiency. This is particularly important in the context of environmental regulations, which are becoming increasingly stringent around the world.

Overall, deposit control additives are an essential component of modern fuels. By keeping engines clean and protecting them from deposit formation, these additives help to ensure reliable performance and minimize maintenance costs. Whether you are driving a car, truck, or other type of vehicle, deposit control additives can provide significant benefits and help to extend the life of your engine

Intake system deposits

Exhaust valve carbon deposits

Injection affect

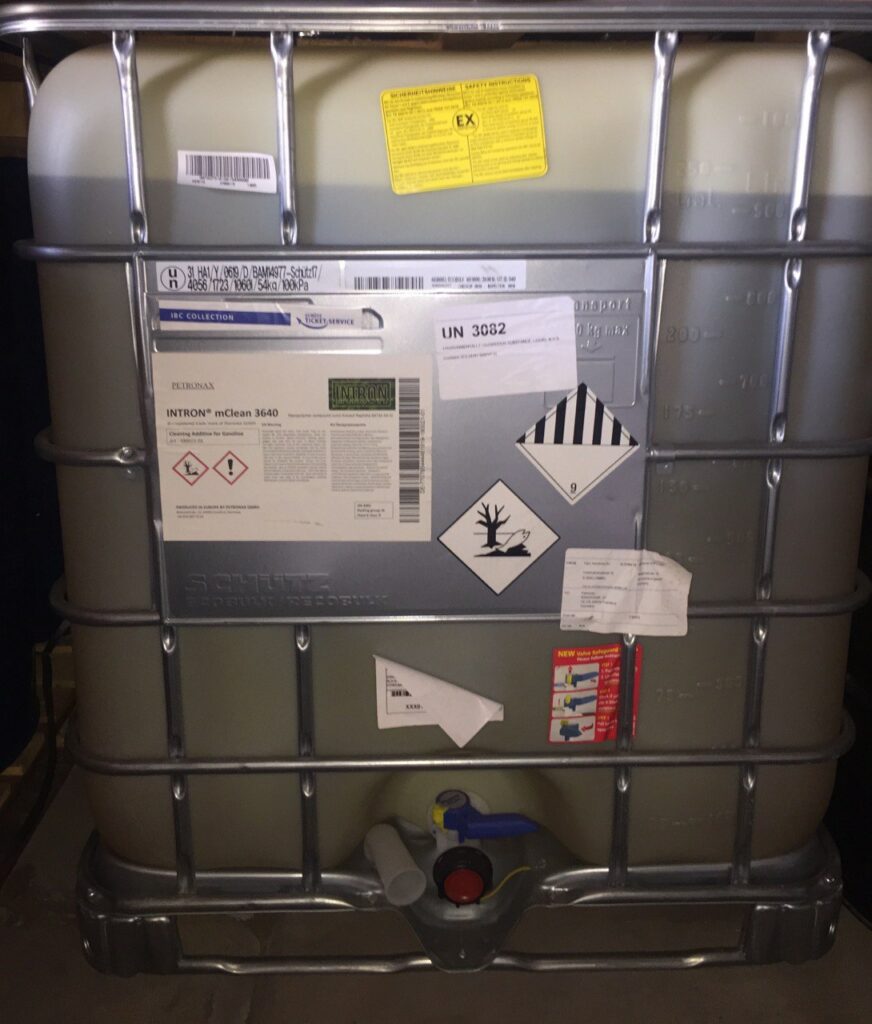

Our research team develop detergent, antirust and defoam additives that are solving the problems during exploitations of standard fuels. Multipurpose fuel additive INTRON® mClean and INTRON® dClean removes existing and prevent fouling new carbon deposits, sorbent water and protect engine from corrosion, defoam diesel fuel, can increase octane or cetane number, low up cylinder friction and reduce harmful emissions of the vehicles engines.

Result after using INTRON® mClean

Result after using INTRON® dClean

Dyes and markers are used to distinguish between different types of gasoline and diesel fuel. Dyes are added to the fuel during production to provide visual identification, while markers are added to provide a more secure means of identification. These markers can be detected using specialized equipment and can help to prevent fuel theft and fraud. Additionally, some countries require the use of dyes and markers for tax and regulatory purposes.

We supply a range of dyes and markers for government fuel regulation and private brands.

Our markers and dyes

- INTRON® Dye Blue

- INTRON® Dye Red

- INTRON® Dye Green

- INTRON® Dye Yellow