The gasoline we use in our cars is a complex mixture of various hydrocarbons, additives, and contaminants. The precise composition of gasoline can vary depending on the crude oil source, refining process, and environmental regulations. However, one of the most important factors that determine the quality and performance of gasoline is its octane rating.

Octane rating is a measure of a fuel’s ability to resist “knocking,” which is an undesirable combustion phenomenon that occurs when the air-fuel mixture in an engine cylinder detonates prematurely. Engine knock can cause damage to the engine and reduce its performance and fuel efficiency. The higher the octane rating of gasoline, the better it can resist engine knock and provide a smoother and more efficient driving experience.

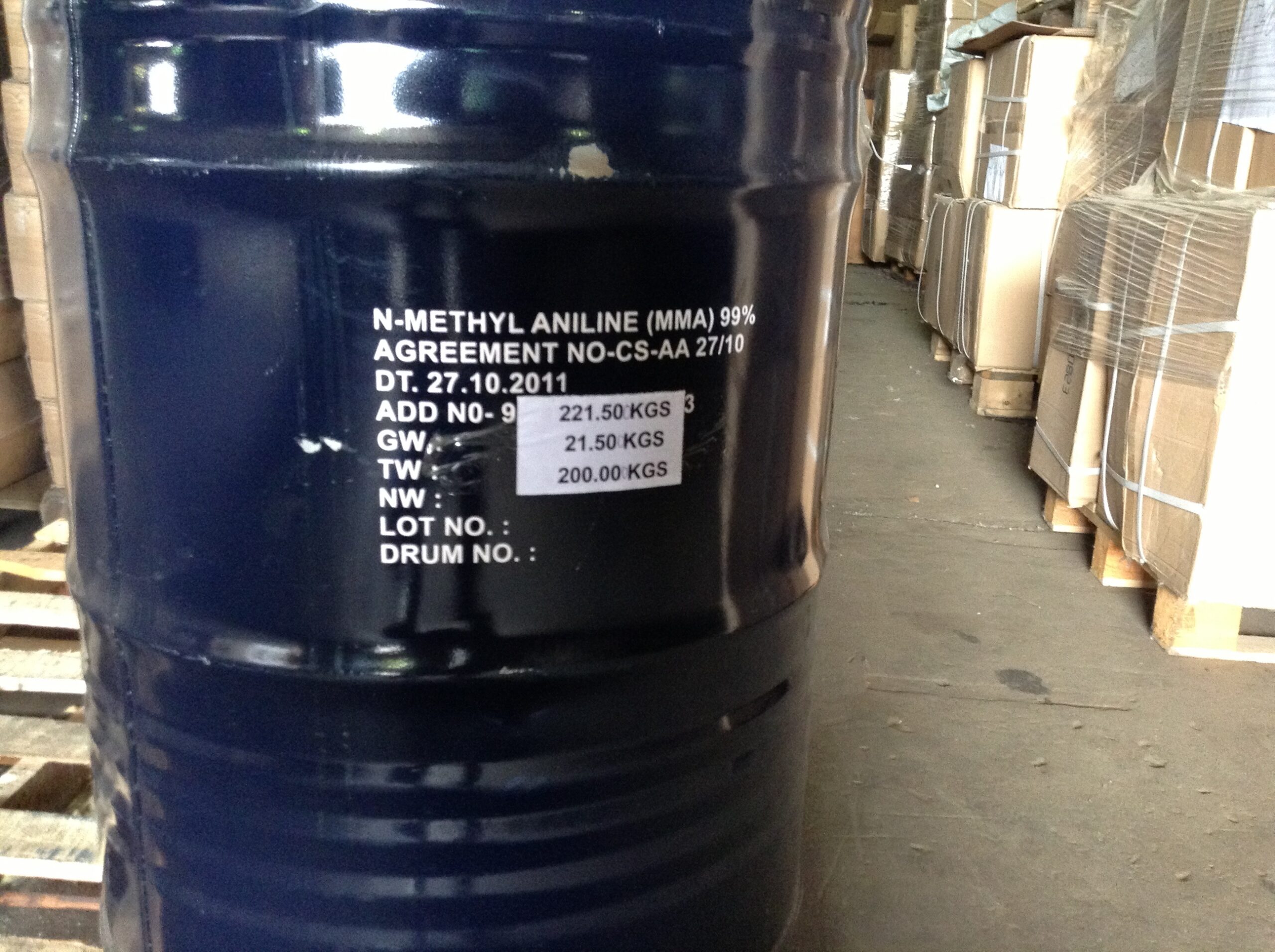

To increase the octane rating of gasoline, various octane booster additives can be used. One such additive is N-Methyl Aniline, a colorless, clear liquid that is widely used in the gasoline refining process. In this article, we will explore the properties, benefits, and applications of N-Methyl Aniline as an octane booster additive.

Properties of N-Methyl Aniline

N-Methyl Aniline (NMA), also known as N-methylaniline or methylphenylamine, is a chemical compound with the formula C7H9N. It is a member of the aniline family, which consists of aromatic amines with a phenyl group (C6H5) attached to an amino (-NH2) group.

NMA is a colorless to light yellow liquid with a characteristic amine odor. It is soluble in water, ethanol, and most organic solvents, and has a boiling point of 197°C. NMA is a weak base and can form salts with strong acids, such as hydrochloric acid (HCl).

NMA is a versatile chemical that can be used in various applications, such as in the production of dyes, pharmaceuticals, and agrochemicals. However, one of the most important applications of NMA is as an octane booster additive in gasoline.

How Does N-Methyl Aniline Increase Octane Rating?

To understand how NMA works as an octane booster, we need to first understand how engine knock occurs. Engine knock is the result of the air-fuel mixture in the engine cylinder detonating prematurely, before the spark plug ignites it. This can happen when the air-fuel mixture is compressed too much or too quickly, causing it to ignite spontaneously.

One way to prevent engine knock is to use gasoline with a higher octane rating. Higher-octane gasoline can resist engine knock better than lower-octane gasoline because it burns more slowly and evenly, allowing for a more controlled combustion process.

However, it is not always possible or practical to produce gasoline with a high octane rating from crude oil alone. This is where octane booster additives like NMA come in. NMA can increase the octane rating of gasoline by slowing down the combustion process, which reduces the likelihood of engine knock.

Specifically, NMA works by delaying the ignition of the air-fuel mixture in the engine cylinder. When gasoline with NMA is injected into the engine cylinder, NMA molecules are first vaporized and then mixed with the air and fuel. As the air-fuel mixture is compressed, NMA molecules absorb heat from the combustion process and undergo a series of chemical reactions, which generate free radicals and other reactive species.

These free radicals and reactive species then react with the hydrocarbon molecules in the air-fuel mixture, causing a chain reaction that eventually leads to combustion. However, because NMA molecules are present, they also react with the free radicals and reactive species, slowing down the chain

reaction and delaying the ignition of the air-fuel mixture.

This delayed ignition allows for a more controlled combustion process, which reduces the likelihood of engine knock. In addition, because NMA is a weak base, it can react with acidic combustion products and neutralize them, preventing them from reacting with the engine components and causing corrosion.

Benefits of N-Methyl Aniline as an Octane Booster Additive

NMA has several advantages over other octane booster additives, such as tetraethyl lead (TEL) and methyl tertiary butyl ether (MTBE). TEL was a popular octane booster additive in the past but was phased out due to its environmental and health hazards. MTBE was another popular octane booster additive but was also phased out due to its potential to contaminate groundwater.

Compared to TEL and MTBE, NMA is a safer and more environmentally friendly octane booster additive. NMA does not contain any heavy metals or halogens and does not produce harmful emissions or residues when burned in the engine. Moreover, NMA is biodegradable and does not persist in the environment like TEL and MTBE.

In addition to its environmental benefits, NMA has several technical advantages as an octane booster additive. NMA is a highly efficient octane booster, capable of increasing the octane rating of gasoline by up to 5-7 points. Moreover, NMA has a low vapor pressure and does not evaporate easily, which means it can be stored and transported safely without the risk of vapor leakage.

Applications of N-Methyl Aniline in the Gasoline Industry

NMA is widely used in the gasoline industry as an octane booster additive. It can be added to gasoline either in the refinery or at the retail gas station. The optimal concentration of NMA in gasoline depends on various factors, such as the initial octane rating of the gasoline, the engine type, and the operating conditions.

In addition to its use as an octane booster, NMA can also be used as a corrosion inhibitor in gasoline. NMA can react with acidic combustion products, such as sulfur dioxide and nitrogen oxides, and neutralize them, preventing them from corroding the engine components. Moreover, NMA can form a protective film on the metal surfaces of the engine, reducing the likelihood of corrosion.

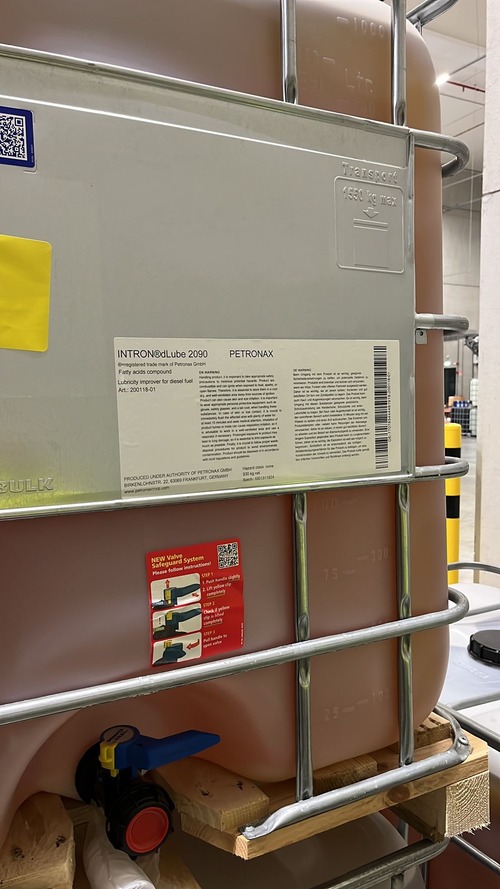

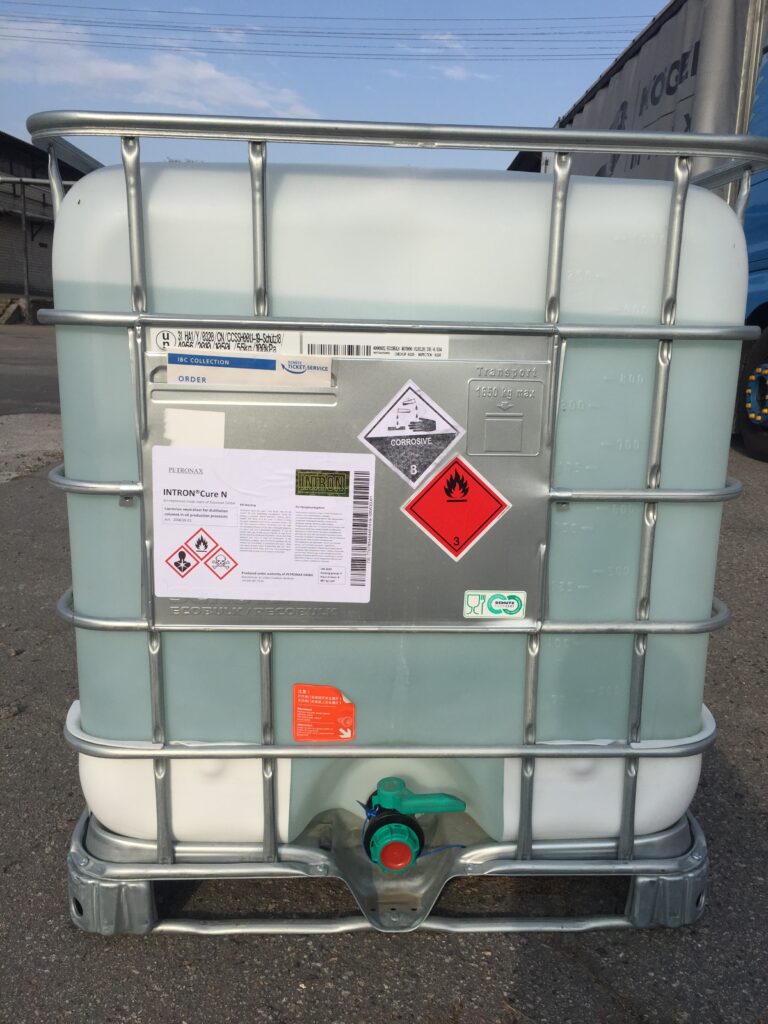

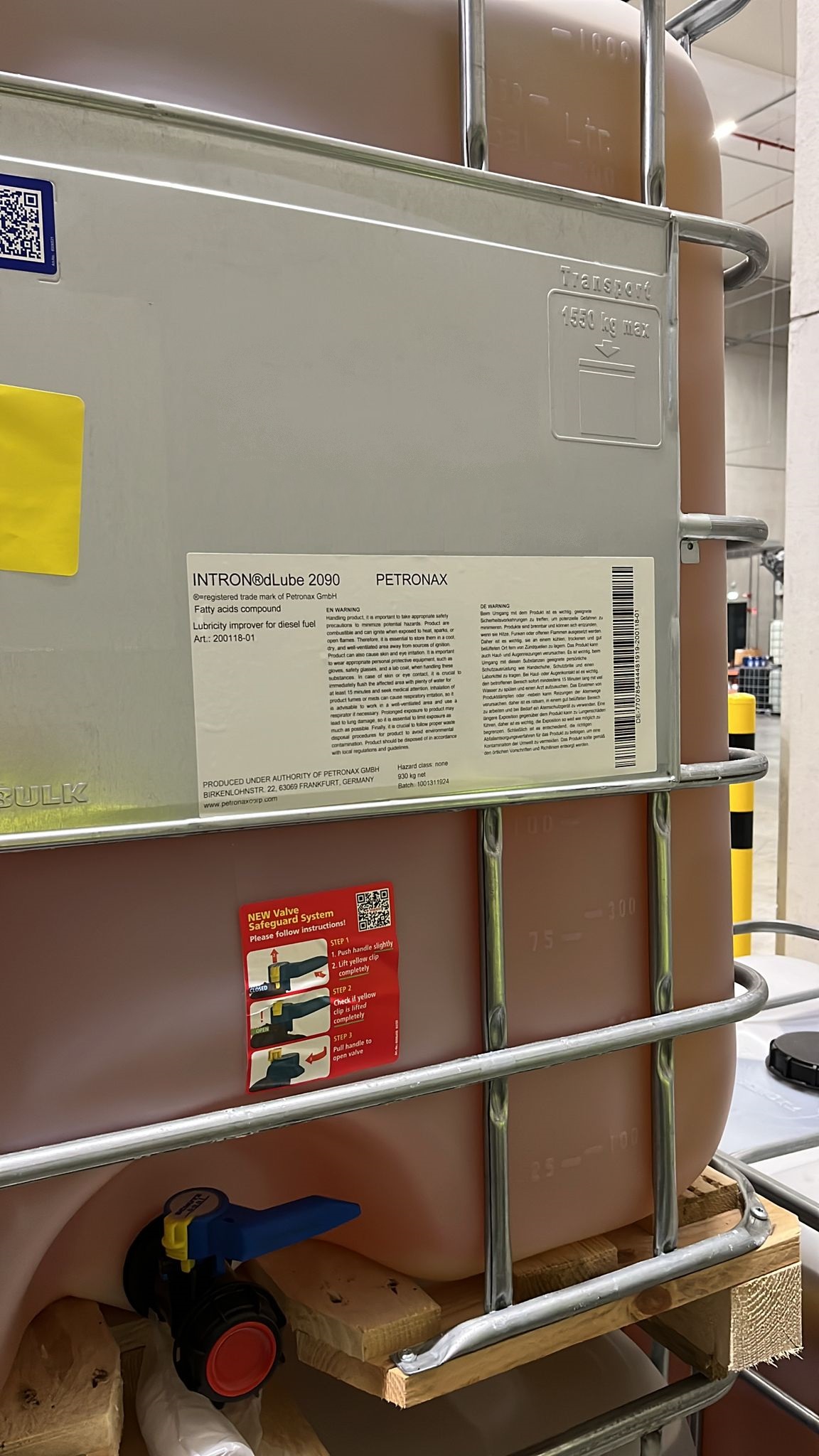

Petronax is a global leader in the production and sale of N-Methyl Aniline as an octane booster additive. Petronax has been producing and selling NMA for over 10 years, serving customers in the United States, Europe, Asia, and other regions.

Petronax’s NMA is produced using state-of-the-art technology and rigorous quality control procedures, ensuring that the product meets the highest standards of purity and performance. Petronax’s NMA is also available in various grades and concentrations, tailored to the specific needs of the customers.

Petronax is committed to sustainability and environmental responsibility. Petronax’s NMA is produced using eco-friendly processes and raw materials, minimizing the environmental footprint of the product. Moreover, Petronax’s NMA is compliant with all relevant environmental and health regulations, ensuring the safety and well-being of the users.

N-Methyl Aniline is a versatile and efficient octane booster additive that can enhance the performance and quality of gasoline. NMA works by delaying the ignition of the air-fuel mixture in the engine cylinder, reducing the likelihood of engine knock and improving the fuel efficiency and driving experience. NMA is also a safer and more environmentally friendly alternative to other octane booster additives, such as TEL and MTBE.

causing gelling that clogs fuel lines and disrupts performance. PETRONAX emerges as a reliable solution provider with its innovative INTRON dFlow, a premier cold flow improver designed to maintain diesel flow in the harshest winter conditions. This exceptional additive alters wax crystal formation to prevent blockages, ensuring engines operate seamlessly when temperatures drop. PETRONAX, a respected company in the oil and refinery industry, leverages extensive expertise to develop products that elevate fuel quality and extend engine life.

causing gelling that clogs fuel lines and disrupts performance. PETRONAX emerges as a reliable solution provider with its innovative INTRON dFlow, a premier cold flow improver designed to maintain diesel flow in the harshest winter conditions. This exceptional additive alters wax crystal formation to prevent blockages, ensuring engines operate seamlessly when temperatures drop. PETRONAX, a respected company in the oil and refinery industry, leverages extensive expertise to develop products that elevate fuel quality and extend engine life.